6th Floor

60 Gracechurch Street

London EC3V 0HR.

Video update from the Clogau St David’s Gold Mine and the processing of the high-grade Waste Tip.

#ClogauGoldMine #Gold #WelshGold

Video update:

https://youtu.be/2xF8svVunYY?feature=shared via @YouTube

In short:

– Exciting foothold in an emerging high-grade lithium province in the world-class Pilbara.

– Focus remains on gold production from Clogau.

More later in interview going out on http://lse.co.uk.

#Gold #CRMs

News today – option over highly prospective lithium licences. More updates soon.

Pleased to say that we’ve collected a large volume of fines material from the Waste Tip trenching programme. We’ve also been making a few adjustments to our processing plant to increase through-put volumes and recoveries. Now onto our next phase of work…

#ClogauGoldMine

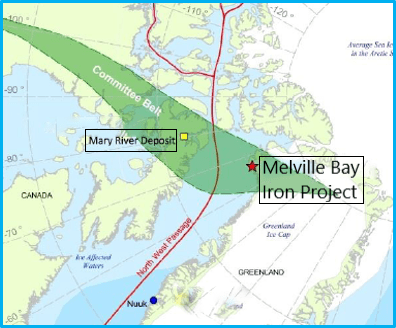

Alba’s 51% owned Melville Bay Iron Project is located within the same geological belt, the Committee Belt, as the world-class Mary River iron ore mine, operated by ArcelorMittal and Nunavut Iron Ore, across Baffin Bay in far northern Canada.

More than 4000 metres of historic drilling at Melville Bay Iron has confirmed the presence of a folded magnetite-banded iron formation (BIF) sequence with a true thickness of 20-50m and a strike length of approximately 2.7km, and has resulted in the declaration of a Mineral Resource Estimate of 67Mt at 31.4% iron (Fe).

Previous exploration targets at Melville Bay Iron have been in the range of 93-269 million tonnes at 27-47% Fe, showing the potential for extension drilling to add significant tonnes to the existing declared resource. Completed metallurgical test work has also demonstrated the ability to produce a high quality, coarse grained magnetite concentrate at Melville Bay, grading 70% Fe, with low impurities (2.0% SiO2, 0.3% Al2O3 and 0.01% P). Several high-grade assay results (more than 60% Fe) and a drill intersection grading 68.2% Fe, indicates that high-grade, high-value Direct Shipping Ore (DSO) iron is found at Melville Bay, in particular at the Haematite Nunatak target.

The potential for DSO material in the Committee Belt is amply demonstrated by the several high-grade deposits which comprise the Mary River Iron Ore Project, including the Mary River Deposit No.1, which has a declared Mineral Resource of more than 350 million tonnes at an average grade of 64% Fe and has been in production since 2014, with iron ore sales of around 4 million tonnes per annum exported to markets in the UK, Europe and Japan.

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The earth’s most important iron ore deposits are found in sedimentary rocks, formed some 1.8 billion years ago from chemical reactions that combined iron and oxygen in marine and fresh waters.

The two most important minerals in these deposits are iron oxides: haematite (Fe2O3) and magnetite (Fe3O4). These iron ores have been mined to produce almost every iron and steel object that we use today. Ores containing very high quantities of haematite or magnetite (greater than about 60% iron) are known as “direct shipping ore” or DSO, meaning they can be fed directly into iron-making blast furnaces.

The primary use of iron ore is in the production of iron. Most of the iron produced is then used to make steel. Steel is used to make automobiles, locomotives, ships, beams used in buildings, furniture, tools, reinforcing rods for concrete, bicycles and thousands of other items. It is the most-used metal in the world by both tonnage and purpose.